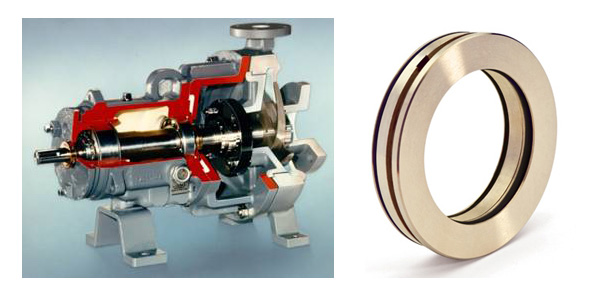

Magnetic seals are considerably more expensive than lip seals.īoth types of contact seals have the advantage of being able to seal positive pressures or static levels (i.e., heads) of lubricant. The primary advantage of magnetic seals over lip seals is that they do not damage the shaft since all dynamic contact occurs within the seal and between the two faces. The faces are usually comprised of different materials such as carbon and stainless steel or other metals. Magnetic seals are optically flat, essentially simple, unbalanced mechanical seals that use magnetic attraction to load faces as opposed to mechanical springs. The primary disadvantages are short life because of wear, and caused by dynamically contacting the shaft they can cause shaft wear and damage. They are also readily available in almost any size required. The primary advantage of lip seals is low cost. The elastomeric contacting element is often retained by a metal housing that is press-fit into the bearing housing about the shaft. This static contacting element is pressed against the shaft, often with the aid of a spring, to ensure positive contact. Lip seals broadly refer to any design that utilizes an elastomeric, usually circumferential contacting element. Contact sealsĬontact seals are commonly further subdivided into lip seals and magnetic seals. For a noncontact seal, contact is not the mechanism by which the seal performs. That is not to imply the design of noncontact seals never permits components to touch (e.g., during installation or adjustment), but rather that contact is not a requirement for proper function. Noncontact seals, conversely, do not rely on contact to perform their sealing functions. If there is no contact, there is no seal. Contact seals rely solely on contact to perform their sealing functions. Contact or noncontact?Įssentially, two broad categories of bearing housing seals exist: contact and noncontact. Basic knowledge and understanding of bearing housing seals is thus a prerequisite topic for any practicing rotating equipment reliability professional. The proper selection and design of bearing housing seals significantly impacts pump reliability. Bearing housing seals primarily provide protection from two major causes of failure: contamination ingress and lubricant loss. Given that bearing failure equals equipment failure, bearing protection is an essential topic to any conversation regarding the reliability of industrial rotating equipment. The practical application of reliability science has made this possible, and attention to bearing life in particular has been a major contributor to this new reality. Where 90-day warranties and annual pump rebuilds were once common, users today have expectations of five years or longer mean time between repair (MTBR). Industrial rotating equipment, particularly industrial pumps, has undergone a similar, though even more dramatic, transformation. Today 100,000 miles is not an accomplishment, but an expectation, and many cars even have warranties that extend that far. A typical new car warranty then was only 12 months or 12,000 miles. The probability that a car would last longer than 100,000 miles was, relative to today, small. The reason was simple: 100,000 miles was a major accomplishment in the late 1970s, and there was little need to record mileage beyond that point. Cars of the 1970s had odometers that rolled over at 100,000 miles.

0 kommentar(er)

0 kommentar(er)